Studying Crystallinity Gradients in High Performance Thermoplastic Composites Manufactures by Automated Tape Placement

Academic Institution: University of Edinburgh

Academic Supervisors: Dr Dipa Roy & Professor Conchúr Ó Brádaigh

Industry Partner: Hexcel

PhD Student: Helena Perez Martin

Summary:

The project focuses on studying composite materials (carbon fibre mixed with a polymer) destined for aerospace applications. The team are looking at how different manufacturing processes and conditions affect the microstructure and performance of the material.

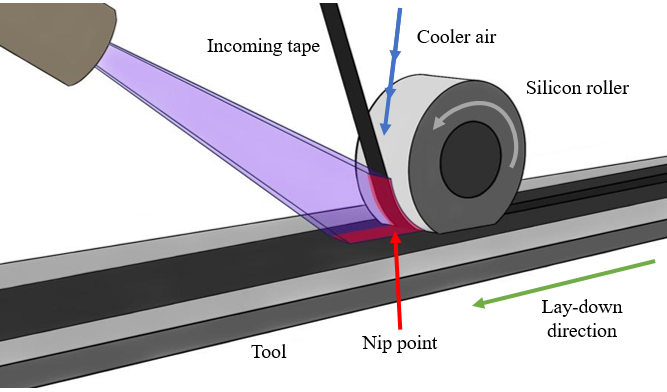

The project’s main objective is to evaluate the impact of Automated Tape Placement (ATP) manufacturing on the crystallinity content and variation across the thickness of carbon fibre/poly(ether-ketone-ketone) (CF/PEKK) laminates, and how this affects mechanical properties. ATP is a high-speed manufacturing technique where composite tape material is heated by a laser as it is being laid down to form a part and pressed in place by a consolidation roller. This heating lasts for a fraction of a second. It is attractive to manufacturers due to its automated nature and shorter production times, but this can result in lower mechanical performance when compared to more conventional manufacturing techniques such as autoclaving or compression moulding. This is because, during ATP manufacturing, materials are exposed to high temperatures and pressures for very short time periods. Therefore, a post-processing step is generally required to achieve the desired crystallinity level in the manufactured part consistently, increasing manufacturing costs. It is therefore important to understand what effect different manufacturing techniques have on the microstructure of the composite material and in turn how this affects mechanical properties, to then optimise processing parameters in ATP manufacturing

Key Results/Outcomes:

· An extensive study of crystallisation morphology and kinetics of unreinforced PEKK and CF/PEKK was performed to understand what the best conditions are to achieve adequate crystallisation in the material, both with and without the presence of CFs.

· Manufacturing, mechanical testing and microstructure evaluation of several laminates under different processing conditions and manufacturing techniques were done, to evaluate the impact of varying parameters and manufacturing methods on the performance of the material:

· Compression moulding: several laminates were manufactured at different isothermal temperatures and cooling rates to observe if different crystalline morphologies are generated, and whether these affect the mechanical response of the composites. There was no significant difference in the performance of these laminates given the performed tests (0° flexural, 90° flexural, ILSS, in-plane shear), and these were observed to perform comparably to what is reported in literature for the more established CF/PEEK composite.

· ATP: several laminates were manufactured varying nip temperature, lay-down speed and roller pressure to observe how these parameters affected laminate performance; as well as to observe how these laminates performed in comparison to the compression moulded laminates. It was observed that nip temperature had the largest impact in the response of the material, and ATP laminates generally performed worse than the compression-moulded laminates.

· Nanoindentation experiments were performed across the thickness of several compression-moulded and ATP-manufactured laminates, in order to evaluate differences in hardness and modulus in the matrix and fibre-matrix interface across the thickness of the laminates, as well as across the different manufacturing methods. These results are currently being processed.

Publications:

Journal publications:

· Pérez-Martín H, Mackenzie P, Baidak A, Ó Brádaigh CM, Ray D. Crystallinity studies of PEKK and carbon fibre/PEKK composites: A review. Composites Part B: Engineering 2021;223:109127. https://doi.org/10.1016/j.compositesb.2021.109127.

· Pérez-Martín H, Mackenzie P, Baidak A, Ó Brádaigh CM, Ray D. Crystallisation behaviour and morphological studies of PEKK and carbon fibre/PEKK composites. Composites Part A: Applied Science and Manufacturing 2022;159:106992. https://doi.org/10.1016/j.compositesa.2022.106992.

Book chapter:

· Ray D, Pérez-Martín H. Chapter 3: Resins for structural Composites. Design and Manufacture of Structural Composites. Editor(s): Lee Harper, Mike Clifford. In Woodhead Publishing Series in Composites Science and Engineering. ISBN 9780128191606. https://doi.org/10.1016/B978-0-12-819160-6.00001-9.

Conference presentations:

· 2021 SAMPE UK student competition finalist. Crystallinity studies of PEKK and carbon fibre/PEKK composites.

· 2021 ICMAC presenter. Processing and characterisation of carbon fibre/PEKK composites.

· 2022 SAMPE Europe Hamburg presenter. Influence of processing paramters on matrix-dominted properties of CF/PEKK composites.

· (Upcoming) 2023 ICCM23 Belfast presenter

Collaborations:

· Mechanical, Aeronautical and Biomedical Engineering Department, University of Limerick: manufacture of ATP laminates.

· Leibniz Institute for Composite Materials (IVW): summer placement performing further microstructure studies of PEKK and CF/PEKK composites. Placement funded by the German Academic Exchange Service (DAAD) through the RISE Professional programme. https://www.daad.de/rise/en/rise-professional/

Contact Information

Helena Pérez Martín

PhD student, Edinburgh University

Dr Dipa Roy

Fellow of the Institute of Materials, MInerals and Mining (IOM3), Edinburgh University

Professor Conchúr Ó Brádaigh

Head of School and Chair of Materials Engineering, University of Edinburgh